Woodfield Systems

Woodfield Systems and Massy Energy, together in Colombia with commitment, quality, experience and support, tailored to your needs.

"Culture is based on the development of quality products and services."

Woodfield Systems, It has the rules ISO 9001: 2008, ISO 14001: 2004, BS OHSAS 18001: 2007, PED: CE y AD 2000-Merkblatt HP0 / DIN EN ISO 3834-2 integrated quality management system and a committed management team, we maintain high international standards.

Product and service offerings

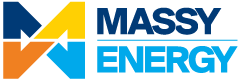

Loading Arms

- Loading or unloading through the opening at the top of the container.

- Fixed range for less frequently used small tank terminals, precise positioning of single compartment (small) vehicles.

- Variable reach (“scissor” design) for medium-sized tank terminals with medium frequency of use, flexible positioning of small single-compartment vehicles.

- Long range for large tank installations with high frequency of use, flexible positioning of multi-compartment vehicles.

All gas loading arms are modularly designed with connection flanges on major components, thereby allowing for easier configuration and improved maintenance capabilities. The inlet flange of our LNG and LPG loading arms will be tailored to the application.

Our loading arms, both in upper and lower connections, are offered with a standard configuration for loading or unloading different chemical and industrial products. For example, some aggressive chemical products require specialized knowledge and equipment for the safety and efficiency in the transfer of these products. Each WSI chemical loading arm has its own specific engineering work to fit the nature of the product to be handled.

Available with

- Jacketed with external steam or oil.

- Electric heating.

- Contra Tracing.

Our pantographs are suitable for use with all types of wide-body and tactical aircraft, helicopters, tankers and fuel dispensing trucks. Ideal not only for applications in large airports (military and civil) and related tank depots with high refueling frequency and low downtime.

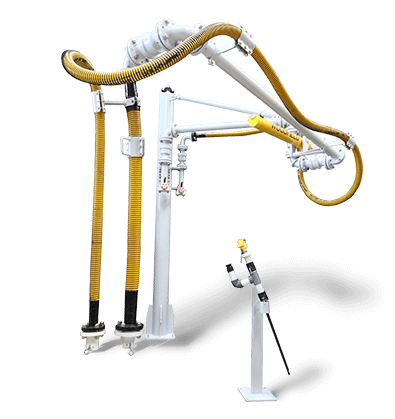

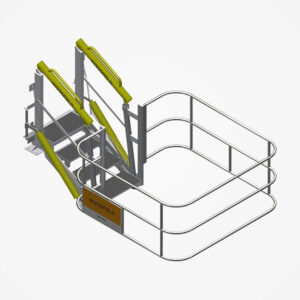

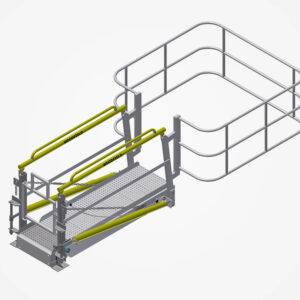

Safe Access Systems

• Materials of construction: aluminum, galvanized steel, stainless steel or fiberglass.

• Standard or customizable widths, depending on your application.

• Non-slip bearing surface for operator safety in dirty and wet environments.

• Spring balance unit with the option of pneumatic or hydraulic operation.

• Manually or motorized sliding walkway systems to allow different access points to the tanker trucks.

Because? Reliable and robust access to the top of ISO tank trucks, railcars and containers from a loading platform is paramount for safe and productive operations in loading, unloading, ventilation and inspection operations.

As? Simple manual or powered operation to lower into position to access the top of a tank from the collapsed position Once the safe working task has been completed, the Gangway is simply raised back to the parked position

Because? Reliable and robust access to the top of ISO tank trucks, railcars and containers from a loading platform is paramount for safe and productive operations in loading, unloading, ventilation and inspection operations.

As? Simple manual or powered operation to lower into position to access the top of a tank from the collapsed position Once the safe working task has been completed, the Gangway is simply raised back to the parked position

Because?

An oversized roll cage allows access to the entire upper portion of vehicle equipment on a tanker, rail car, or ISO tank container without the need to redetect the vehicle. Ideal for safe and efficient loading, inspection, sampling or venting operations with multi-compartment tanks or where full access to the top of the tank is required

As?

Safe access from the platform to the top of the vehicle is via the folding stairs once the LAFS unit has been lowered into position. The entire work area on top of the vehicle is now surrounded by a roll cage. Once safe work tasks are completed, the unit is simply raised into the stowed position

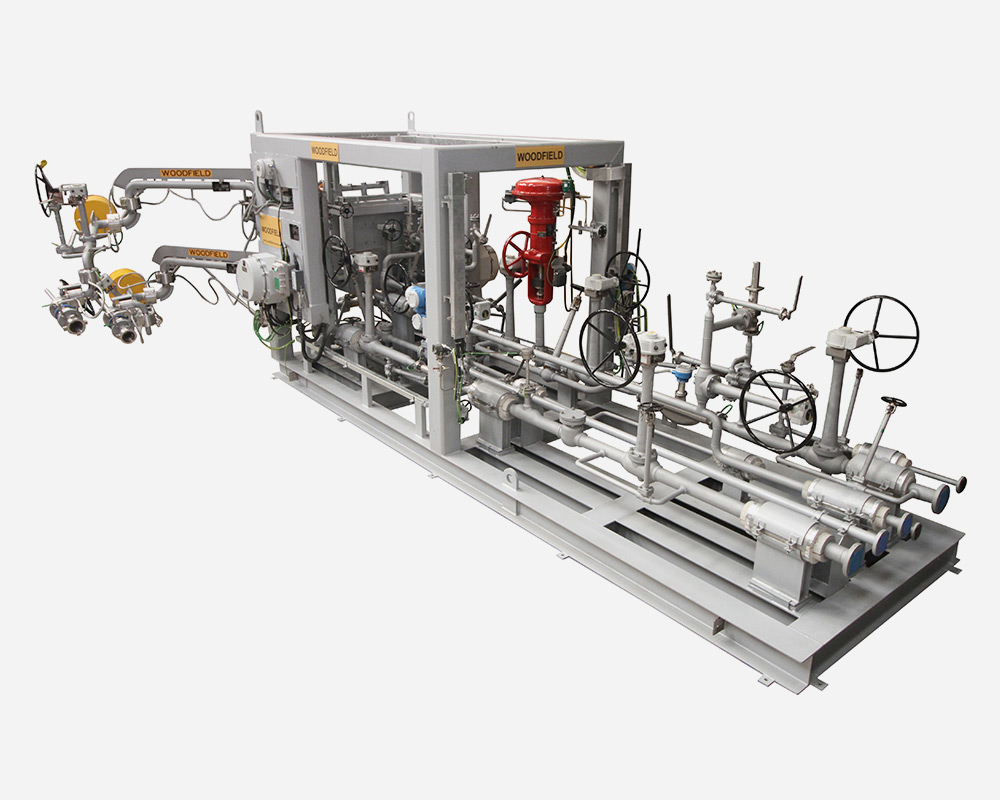

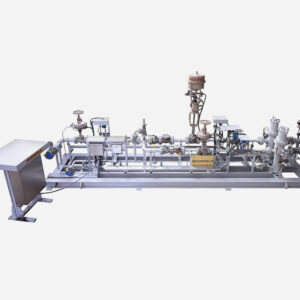

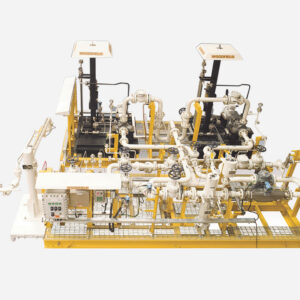

Solutions on skids

The supply to the Oil & Gas, Petrochemical and Chemical loading skids are designed and manufactured in accordance with the latest industry standards and local regulations.

These measurement skids are custom designed based on customer specified process parameters and control philosophy.

Designed to accommodate Top or Bottom Load/Unload, these fully integrated load metering skids (manufactured and tested) primarily consist of load arms, flow meters (PD, Coriolis, or Turbine depending on process requirements), batches, instrumentation & other associated piping, electrical and structural steel components.

The transportation of LNG by means of tanker trucks is the most standardized and economical way to reach consumers throughout the country. Therefore, the loading of LNG tankers using LNG loading skids is an important and critical process in the transportation of LNG by road.

Loading LNG into a tanker is difficult due to its cryogenic process condition (-176 degrees C). However, with Woodfield’s strong engineering, manufacturing and testing capabilities, it becomes easier for the terminal operator to fill trucks with LNG, safely and efficiently.

Woodfield manufactures Cryogenic truck loading arms and truck loading stations with typical capacities ranging from 30 m3/hr to 100 m3/hr and available in sizes 3″150# & 4″150#. These skids are designed for a process temperature of -196 degrees C to +80 degrees C.

LPG is produced with a perfect mixture of Propane and Butane. The Propane and Butane mixing process is done with the LPG mixing system.

Woodfield manufactures LPG blending stations to meet the requirement for accurate blending of Propane and Butane. It is important that the composition of the LPG, i.e. the composition of the ratio of Propane and Butane is kept precisely as per the customer’s requirement.

Woodfield provides LPG blending stations with typical capacities of 60 to 70 m3/hr with sizes ranging from 2″ 300# to 4″ 300#. This station mainly consists of propane and butane flow measurement and control lines, static mixer, vapor pressure control system, relief valves, mixing controller and other associated piping, electrical and structural steel material.

To ensure reliable and safe unloading and pumping of tankers for Oil & Gas and Power Generation companies, Woodfield supplies its unloading and pumping meter stations using a centrifugal pump that meets the requirements of the API 608 standard.

These meter stations are custom-built pump and discharge skids and are designed based on the end user’s discharge capacity requirements, process condition, configuration, service, type of pumps, etc.

Woodfield provides these types of discharge meter stations with capacities from 50 to 120 m3/hr with sizes from 3″ to 4″ and pressure ratings of 150#/300#. Discharge metering stations consist primarily of motorized pumps, strainers, discharge arm/hose, flow meter, recirculation line valve, relief valves and other associated valves, piping, electrical, and structural steel hardware.

We offer the pump motor, meeting the client’s local statutory requirements for hazardous atmosphere certifications such as IEC / Atex / NEMA

LACT skids are used to transfer process fluid with fluid property change. These skids are very precise and accurate for the measurement of the sale and the settlement of invoices. These skids come with certified flow meters for custody transfer. Its precision varies between 0.05% and 0.5% of the flow.

Depending on the service, flow measurement technology varies from Coriolis, PD, Turbine and Ultrasonic. Typically these metering stations range in capacity from 20m3/hr to 2000m3/hr with a size range of 2″ to 24″ with a pressure class of 150# to 900#.

These flow measurement skids are equipped with flowmeters that comply with the API MPMS Chapter 6 custody measurement standard for liquid measurement and AGA for gas measurement to be used by the end user.

Woodfield’s Dosing Skid Solutions are used to dispense a preset amount of chemical into the process pipeline at the desired rate.

These skids have low flow rates and the skid is kept close to the point of injection. Chemical storage tanks are skid mounted to store the chemical to be dispensed. PD pump according to API 675 to feed the chemical product in the process line.

The pump capacity can vary with the setting, either manually or automatically.

A control panel is provided to operate the pump locally. These chemical dosing meters are available with capacities ranging from 2 LPH to 2000 LPH for dosing.

Skate Size and Rating: 1/2” to 2” 150# / 300# / 600#.

To meet the need for package process control and terminal operating efficiency, Woodfield provides customized process control and automation system solutions.

PLC Based Process Control System

It consists of a PLC based process control system to monitor and control the process of loading / mixing / dosing etc. This consists of a PLC panel typically mounted in a secure area with other ancillary devices within the panel, including a portable engineering workstation and an operator workstation with SCADA software. The system is pre-programmed and ready to use with full on-site support to integrate the system with the customer’s supervisory control system, ie the DCS.

Terminal Automation System

A complete automation system is provided for various terminal operations such as tanker entry, check-in, order booking, truck access, cargo pump control, truck loading, inventory management of tank farms, billing, truck departure, CCTV integration, etc.

The system consists of a complete PLC-based loading control system or batch controller-based loading control system, tank truck input and output system, weighbridge integration, pump control, DCS, etc

The TAS system is geographically distributed but centrally integrated into the load rack servers and load automation software is provided for the operator interface

Floating Suction Unit

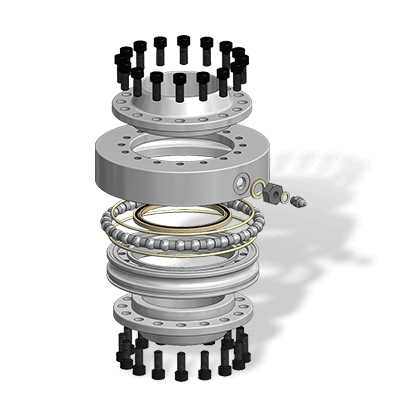

Swivel Joints

Swivel joints are high precision devices that support the axial and radial load of the loading arm and, at the same time, carry the product under pressure and allow the loading arm to rotate and make the connection. At the same time they are capable of handling system or ambient temperatures from +230°C to -196°C.

Each Woodfield Systems Swivel Joint design is independently tested and certified by TUV to provide confirmation of:

– Durable leak-free life under maximum operating conditions.

– At continuous mechanical load.

– At maximum continuous pressure or temperature

Accessories

Customized solutions according to your need

Precision, maximum safety and state-of-the-art technology.

- State-of-the-art design and engineering.

- Immediate response.

- Customized bulk fluid handling solutions.

- Safe access solutions for loading and unloading of fluids.

- Oil & Gas, Chemical, Petrochemical, Cryogenic and Aviation.

Woodfield Product Portfolio

-

Loading / Unloading arm for oil with connection at the top

-

Loading / Unloading Arm for compressed or liquefied gases

-

Loading / Unloading Arm for Chemical / Industrial Sector

-

Heated Loading / Unloading Arms

-

Aircraft refueling arm

-

Folding Ladders (FS)

-

Access Gateways (G)

-

Wide Access Folding Ladders (LAFS)

-

Fast platforms

-

Tank Truck & Railway Car Load Measuring Skids

-

LNG Truck Load Measuring Skid

-

Solution for LPG Mixing Skid

-

Truck unloading and pumping skids

-

Automatic Custody Transfer Skid (LACT)

-

Solution for Dosing and Chemical Injection Skids

-

Customized control and interface systems