Woodfield

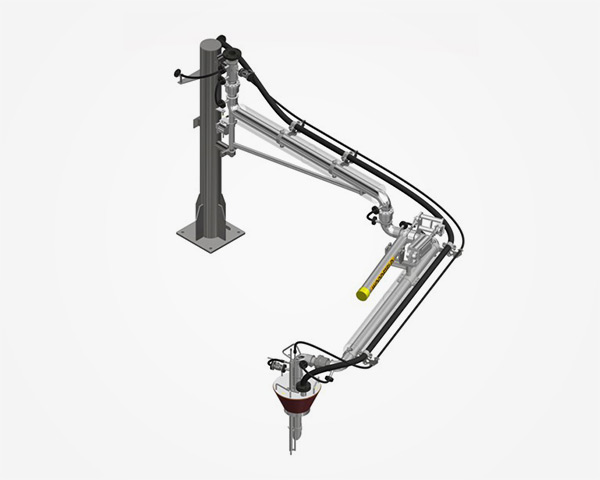

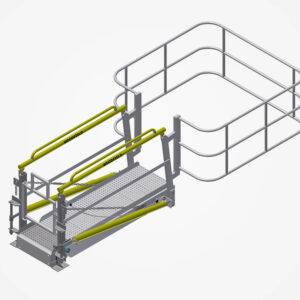

Heated Loading / Unloading Arms

The variety of difficulties encountered in loading and unloading are greatest in the chemical and industrial products industry. Many products such as liquid sulfur, bitumen and some crude oil derivatives require specific treatment at an elevated temperature during the transfer process. In extremely cold climates, heated arms are used to prevent the product from solidifying. This is why all WSI loading/unloading arms have their own heated model.

Heated Loading / Unloading Arms

Available with:

- External steam or oil jacketed.

- Electrically heated.

- Counter-Tracing.

All arms come with custom insulation sleeves to reduce heat/energy losses. Insulation sleeves are removable for inspection/maintenance. Aluminum cladding insulation is also available. WSI’s range of Upper and Lower heated loading/unloading arms are specifically designed to work with the exact nature of each liquid or vapor, both inside and outside of tank trucks, railcars and ISO containers. For all liquids and vapors that depend on their temperature WSI has a specific solution to handle each application safely and satisfactorily…

All WSI loading arms are designed and manufactured with our ISO certified quality management systems and in line with the ASME B31.3 Process Piping code. 100% of the assembled loading arms and swivel joints have passed hydrostatic testing. Liquid penetrant and X-Ray tests will be carried out as per required specifications. Complete fabrication documentation and MTR can be provided for each loading arm. Standard paint finishes for carbon steel are done by SA 2 ½ SA Shot Blast process and RAL 7035 Polyurethane finish. Other paint characteristics are also available. If required, TPI will be provided.