Woodfield

LPG Mixing Skid Solution

LPG is the main source of cooking gas in major countries around the world. To meet the growing demand for LPG, we have been constantly improving the infrastructure of the production and distribution network.

LPG is produced from a perfect blend of Propane and Butane. The Propane and Butane blending process is done with the LPG blending system.

Woodfield manufactures LPG blending stations to meet the requirement of precise blending of Propane and Butane. It is important that the LPG composition, i.e. Propane and Butane ratio composition is accurately maintained as per customer’s requirement.

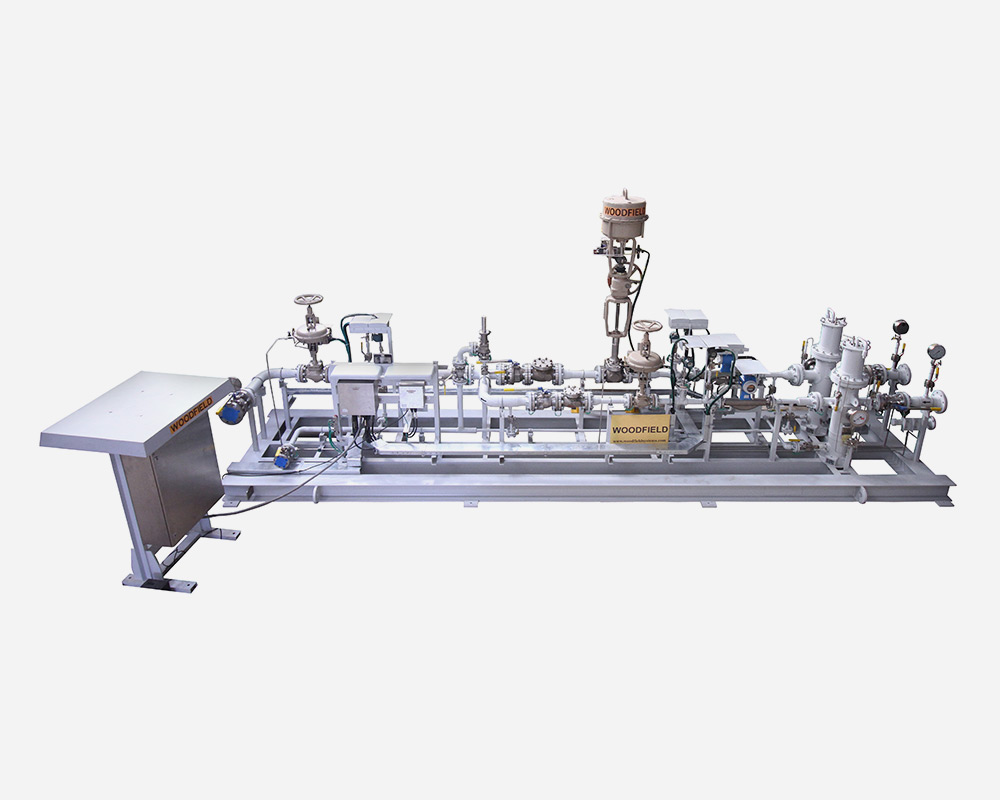

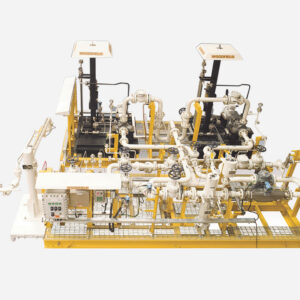

Solution for LPG Mixing Skid

Woodfield provides LPG mixing stations with typical capacities of 60 to 70 m3/hr with sizes ranging from 2″ 300# to 4″300#. This station consists primarily of Propane and Butane metering and flow control lines, static mixer, vapor pressure control system, relief valves, mixing controller and other associated piping, electrical and structural steel material.

Features

- Fully integrated closed loop system with on-line analyzer to monitor and control the mixing process.

- In-house manufacturing (meaning fabrication, assembly, system integration and test center) on a single frame makes it a “plug and play” device and ensures minimal on-site labor.

- Reliable, accurate and efficient operation of the mixing process.

- Easy to customize the mixing ratio using an input keyboard ranging from 20% to 80% of the main product.

- The complex process of ratio mixing control is facilitated.

- Customized flow capabilities can be achieved.

- Optional integration of RVP analyzer.