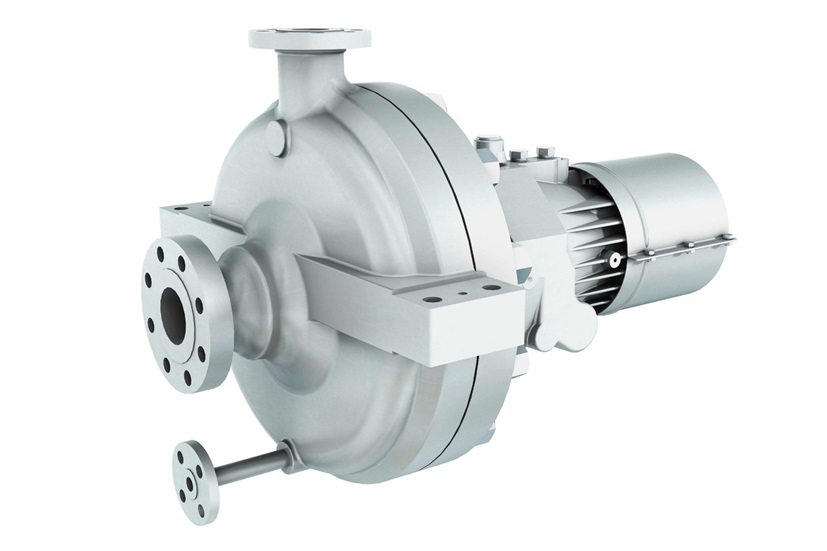

Sulzer

OHHL PUMP

The OHHL is our API 610 (ISO 13709) horizontal cantilever process pump, type OH2, low flow. It covers the low flow end of the OHH coverage range. The unique low-flow impeller design provides gap-free coverage for any high-pressure, low-flow application. Bearing support and mechanical seals on OHH pumps are used to reduce spare parts inventory.

OHH/OHHL SINGLE-STAGE CANTILEVER PUMP ISO 13709 / API 610 OH3

OHHL low flow, high pressure pumps

FEATURES AND ADVANTAGES

– Stable flow-head curves obtained thanks to the unique low-flow impeller-diffuser design

Low flow, high pressure, chevron-free coverage

-Heavy duty flange loading option with 2x ISO 13709 (API 610) flange loading option

ISO 21049 (API 682) cartridge type mechanical seals for reduced emissions -Swappable parts reduce emissions

Interchangeable parts reduce spare parts inventory -Spare parts for reduced emissions -Spare parts reduce spare parts inventory

KEY FEATURES

Flow rates From 1 to 60 m3/h/4 to 260 gpm (gallons per minute)

Heights 20 to 450 m/65 to 1500 ft (20 to 450 m/65 to 1500 ft)

Pressures Up to 51 bar/ 740 psi (pounds per square inch)

Temperatures From -75 to 425 °C/-100 to 800 °F (-75 to 425 °C/-100 to 800 °F)

APPLICATIONS

– Seawater booster for critical services

-Recirculating services

High pressure make-up water services -High pressure make-up water services

-Light hydrocarbon booster

Light Vacuum Gas Oil (LVGO) and Heavy Vacuum Gas Oil (HVGO) services -Light Vacuum Gas Oil (LVGO) and Heavy Vacuum Gas Oil (HVGO) services